Date posted: July 15, 2011

– Download What soldering iron do you prefer? as PDF –

A viewer on our youtube channel asked about soldering iron recommendations. Of course, if you’re going to get into RC beyond buying everything ready to go, and especially if you’re going to jump into electric flight, you’re going to need to solder. More often than not you’ll purchase a speed control, a battery, a transmitter, a charger… something that will eventually require you to either purchase or make adapters, or cut some wires and solder your own.

Although for this Q&A I won’t go into soldering basics, we’ll just stick with what I’m using at this point and why.

I think since I started RC I have tried about five different soldering irons. We have the classic soldering iron, the plastic or rubber grip with the long metal tube-o-heat that is normally twice the length of the handle itself, passed down from your father and his father before him. The tip has oxidized beyond belief, and on a good summer day outside it may just melt butter in the sun. You can also pick up new versions of these at your local hobby store or radio shack. Needless to say, while they work, I always found that style to go along with being under-powered and unwieldy. Oh, then there were the ‘guns’… I’m not a fan of those for RC and electronics, once again, unwieldy.

I carry around a butane powered soldering iron at the field with me in case we really need to do one of those repairs. A gift from my parents, it’s never been used at the field, but damn it all, I AM ABLE AND WILLING TO SOLDER SHOULD THE NEED ARISE.

At home, though, I finally settled on the Weller WPS18MP PRO Series 60 Watt Soldering Iron. The link is riiiiiiiight here. I saw it at my local hardware store and although it wasn’t love at first sight (if it was, I’d check myself into Bellevue immediately), but I was curious enough to try it out. Okay… I admit it. I love it. It’s got the wattage I need for basic RC and electronic soldering, it’s got a textured hand held grip, a small LED to light your work, and a small replaceable tip that plugs into the base unit. The conical tip is great for your RC soldering needs, and your hand is much closer to your work based on the tip length and how the iron is designed to be held. Given the design, you can also lay it sideways and the tip won’t touch the table, you don’t really need a soldering iron holster. Although, I still like to at least prop it up against something non-combustible because I am a clutz. A drawback, though, is that you can’t use run of the mill tips, if you need to replace a tip, you’re forced to buy replacements that are specifically designed for this iron. (FYI, that tip is Weller Part #WPS10).

I’ve not needed to replace the tip yet, even after having this for over a year. It heats up quickly, has a red/green LED to let you know it’s ready to go, and is my preferred soldering iron for any electronic circuit and RC soldering I’ve had to tackle thus far.

I suppose I should also mention a few of the other related tools I like to use with this soldering iron, namely the solder and a cleaning utensil. For solder, I like extremely thin 60/40 rosin core solder. I haven’t needed anything other than this, no separate flux required. Tin the tips of both wires or connectors, heat, connect, and you’re done. The reason I say extremely thin is that I’m often soldering 2 or 3mm bullet connectors to the ends of my motor and ESC leads. Thick solder wire is a bit of pain to work with in those cramped spaces, or on the simple little circuit boards I’ll occasionally tinker with. We’re talking .031 diameter thickness.

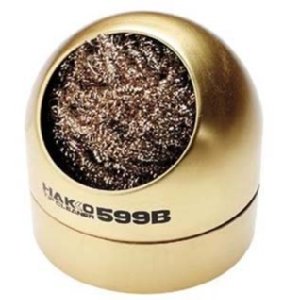

As for cleaning, you have a couple of options… The wet sponge/old t-shirt/used handkerchief method is what I used to use, and although it worked, you really had to make sure the cleaning cloth was… well… clean. The water should also be pure to keep the tip in (wait for it) TIP-TOP SHAPE. Then I stumbled upon this little guy:

I found it on Amazon while browsing around one day (photo taken from Amazon.com), and after trying it out, I’m sold. No more having to wet a sponge, if you have a bit of solder-glob to remove, just feed the golden pac-man a 60/40 pellet from the tip of your soldering iron. The instructions are so simple that they’re too easily turned into innuendo.

- Thrust in

- Twist around

- Pull out

It’s really that simple, but take a moment to get your mind out of the gutter and back on to soldering. Ready? No? Okay… How about… Now? Yes? Good.

The brass coils are supposed to be softer than the tip of your soldering iron itself, which should play nice with a little game I like to call longevity. The reviews on Amazon are solid, and I have to agree with them.

So there you have it, it’s what I use, and while your mileage may vary, the soldering iron, solder, and tip cleaner that sit on my desk have been serving me faithfully for some time now, and my cold solder joint days are well in the past.

Even if you don’t like the products above, regardless of what you choose, here are some thoughts on soldering in general:

- I prefer 40 watts at a minimum. I want heat on, solder joint melting, and heat removal. The less time the tip of my iron is melting solder on electronics the better.

- Use a solder meant for electronics. If you don’t have a flux core solder like the 60/40 rosin core I prefer, get yourself some flux to help ensure less cold solder joints. MAKE SURE THE FLUX IS FOR ELECTRONICS.

- Make sure it’s a comfortable fit for you – if you don’t have good control over your tool, you’ll burn yourself (experience talking, good blister on that one) or melt a bit more than you bargained for.

- For electronics and smaller RC components, thinner solder wire is better – less over-spill and the solder melts faster.

2 Comments

EJ

15/07/2011

I’ve used the “gun” type for years. After my last one died, after about 30 years, I picked up a 140/100 watt Craftsman. I also will use a 60 watt iron, when I’m have a lot of soldering to do at once, and need to keep a sustained heat. Your Weller example looks nice. May look into that one for delicate uses. Really like the cleaning tool. I’ve always hated grabbing the tip with a wet cloth.

Thanks, for the HOT tips,

EJ

optimistONE

15/07/2011

I still use my el cheapo Radio Shack soldering iron. Although I am glad to have the above link handy when I want/need to upgrade. For those out there who are soldering new connectors for their lipo batteries, make sure you don’t touch the exposed wires (black and red) from the lipo or there will be a spark and probably a short therefore rendering your lipo useless all together. Great article E.

No trackbacks yet.